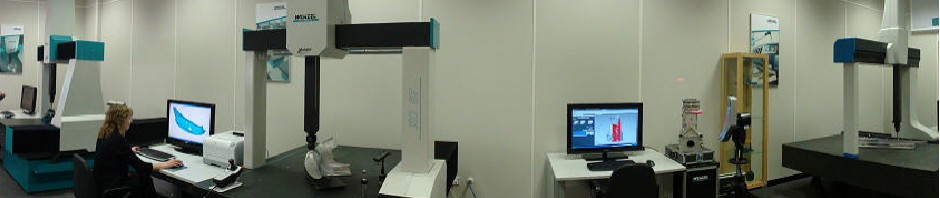

Dimensional Measurement (DMI) offers a wide array of A2LA calibration services, which can be performed in our lab or on-site at your facility. DMI possesses the knowledge and tools necessary to expertly certify precision hand gages, set up tools, and a wide variety of dimensional measuring tools.

The following is a small sample gages that DMI is accredited to certify:

Micrometers

Rules

Depth Gages

Angle Plates

Set-up (1,2,3) Blocks

Straight Edges

Dial Indicators

Precision Balls

Height Gages

Pin Gages

V-Blocks

Surface Roughness Patches

Calipers

Squares

Bore Gages

Plug Gages

Ring Gages

Profilometers

In addition, DMI offers accredited certification for custom fixtures and in-process gaging. Our dimensional calibration service for these custom gages frequently requires only the part print. From that information, our experienced metrologists can perform reverse engineering on the gage and determine its conformance to the part’s requirements.

We have the capability to perform complex dimensional calibration and inspection of fixtures using the part drawings, part CAD models, design specifications, sketches, or simply a description of the gage’s intended use.

Almost universally, accredited gage certification is now required for all quality systems. DMI’s metrologists will not only provide this gage calibration, but will assess the condition of the gage and identify any issues that may affect its usefulness. Any gage repairs that may be needed can also frequently be sourced through DMI.

As mentioned above, we offer both on-site gage calibration of standard gages and hand tools, and also on-site dimensional calibration of specialized equipment and gages.

However, due to the limitations of portable equipment and varying environmental conditions, please contact us to discuss your particular needs so that a successful course of action can be provided.